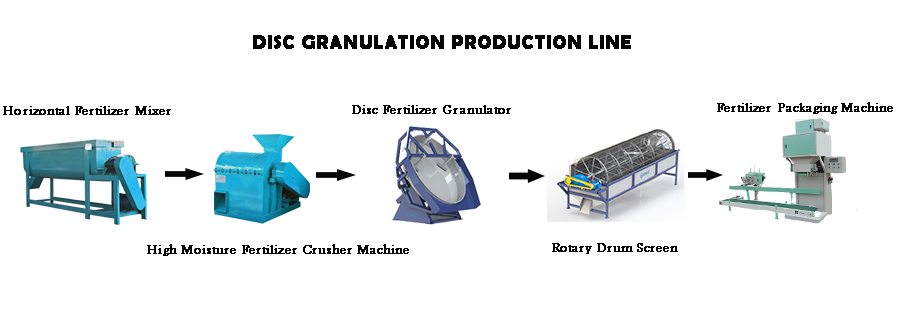

Disc granulator is a common tool for organic fertilizer granulation. The specific production process is as follows:

Disc granulator is a common tool for organic fertilizer granulation. The specific production process is as follows:

(1) Crushing and mixing: The fermented and decomposed animal powder organic fertilizer raw materials are crushed to make them reach the appropriate particle size, and then transported to the horizontal mixer for mixing, and then transported to the granulator to feed the bin.

(2) Feeding and granulation: the powdery raw materials are evenly fed through the feeding bin, and fed into the disc of the disc granulator at a uniform speed; according to the moisture condition of the material, it is sprayed on the disc by the automatic moisture shower of the disc granulator. The surface of the material in the disk makes the powder reach a reasonable humidity; the powder uses the centrifugal force of the disk rotation and the friction force of the disk to produce axial rolling. During the rolling process, the powder particles are kneaded and squeezed to form a moisture comparison Large organic fertilizer particles.

(3) Drying and cooling: The moisture-rich fertilizer particles are transported to the organic fertilizer drum dryer by a belt conveyor. During the tumbling process of the particles in the dryer, the heat energy blown from the hot blast stove is converted to achieve drying. The granular organic fertilizer is dried to a reasonable water content and then transported to the cooler, where the temperature is quickly reduced. The cooled particles are sent to a sieving machine to achieve particle classification.

(4) Screening and coating: In the drum screening machine, the qualified organic fertilizer particles are sent to the coating machine through the conveyor for coating; the unqualified particles are transported back to the crushing and mixing process before being granulated.

(5) Packing and warehousing: the coated particles are measured and packaged by a fully automatic weighing and packing scale, and then warehousing.

(6) Dust removal process: drying, cooling, and workshop dust disposal, using cyclone dust collector or water curtain wet dust removal three-stage treatment, and emptying after reaching the standard.

Post time: Nov-26-2021