-

Installation and test machine of Stirring Tooth Granulator: 1. The equipment should be installed on a level concrete foundation and fixed with anchor bolts. 2. Pay attention to the verticality between the main body and the horizontal when installing. 3. After installation, check whether the bolt...Read more »

-

Pig manure is fine in texture and contains more organic matter and nutrients such as nitrogen, phosphorus and potassium. It has the characteristics of slow decomposition and is suitable for base fertilizer. Under the conditions of modern pig raising, the use of pig manure to produce organic ferti...Read more »

-

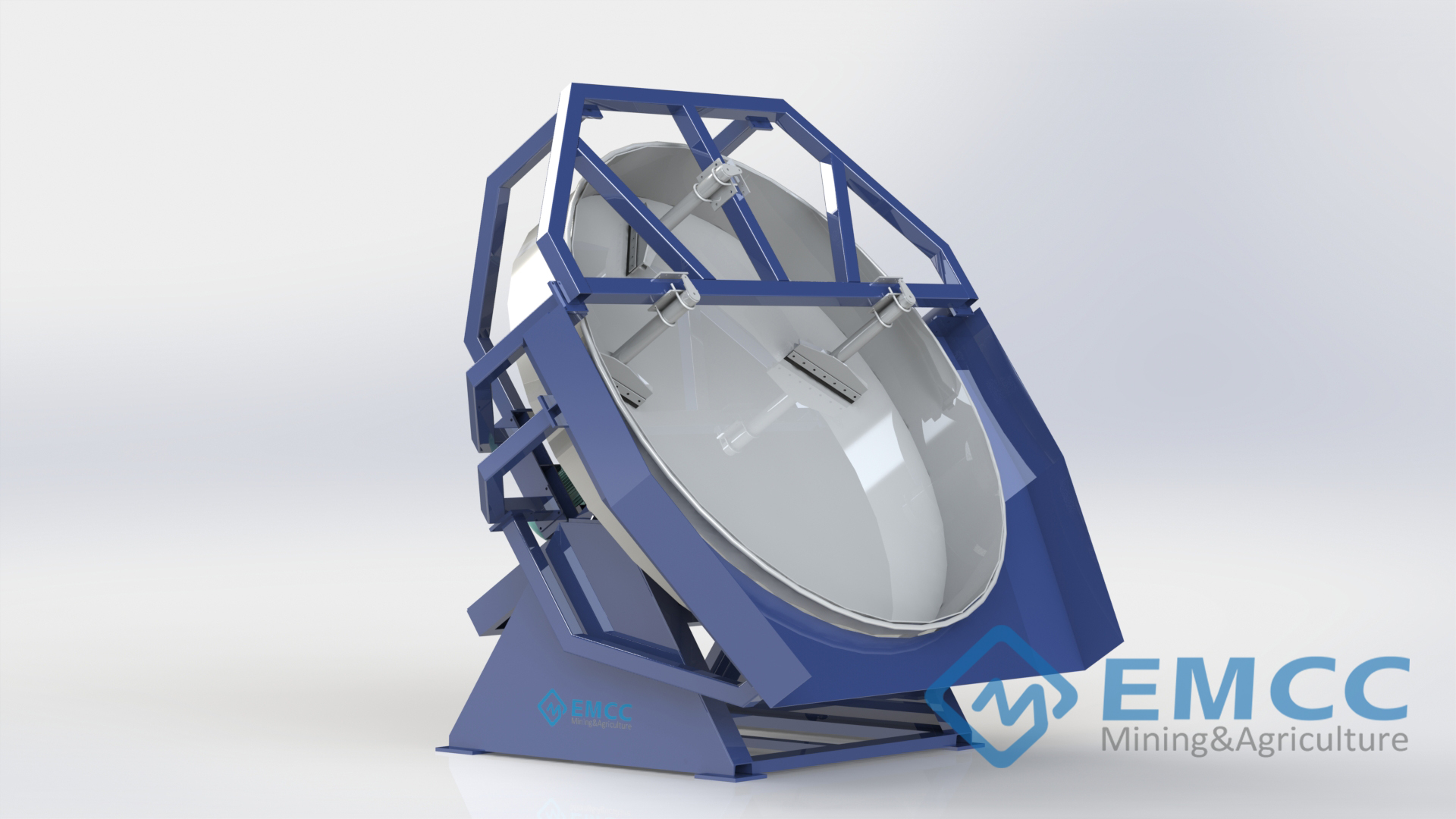

1、Turn on: Before turning on, check whether the reducer is filled with gear oil and whether the direction of rotation of the disc is correct. 2、Running: After pressing the start button, the host starts, and observe whether the equipment is operating normally, whether there is vibration, and wh...Read more »

-

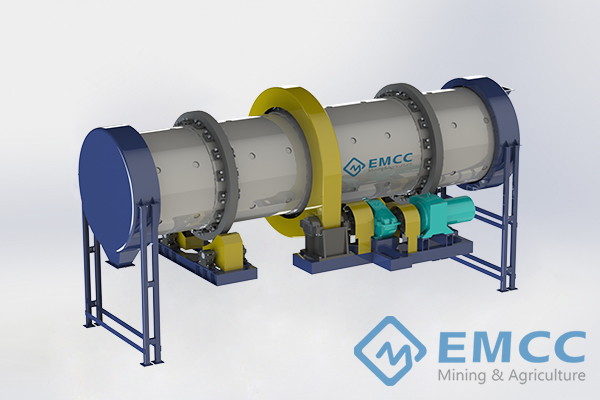

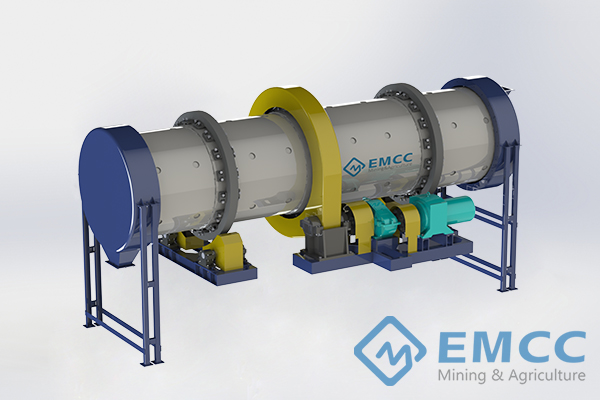

Rotary drum granulator fills the engine room with steam, gaseous ammonia, phosphoric acid or nitrogen solution or supplements water, so that the dry material can be agglomerated into balls through the rotating motion of the cylinder under a certain humidity and temperature. The organic fertilizer...Read more »

-

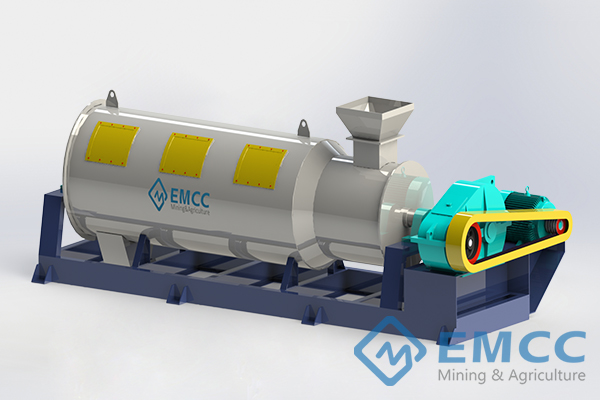

Product Description: The tooth stirring granulator is widely used in the granulation of organic and inorganic fertilizers. Due to the high granulation rate, stable operation, durable equipment and long service life, it is selected as the ideal product by the majority of users. The shell of the to...Read more »

-

The sulfur coating controlled release complete set of equipment is a new environmental protection process, which wraps the molten sulfur on the surface of urea particles and the sealing material, and is a coated fertilizer with slow-release effect. Sulfur coated urea generally contains 10% ̵...Read more »

-

The complete set of equipment for resin-coated slow- and controlled-release fertilizer uses polymer resin with very low water permeability as the coating material, and coats it evenly on the surface of the fertilizer particles to form a layer of resin with very low moisture dialysis. The water in...Read more »

-

The livestock and poultry manure tank fermentation machine adopts the principle of aerobic fermentation, using the organic matter, residual protein and microorganisms in the livestock and poultry manure, and under a certain temperature and humidity, the organic matter and protein in the manure a...Read more »

-

The fermentation tank device is composed of a cylinder body, a sealing system, a feeding and discharging system, a supporting wheel group and a blocking wheel group, an air supply, and an exhaust gas treatment system.: The cylinder rotates on the roller set through the driving system; the materi...Read more »

-

There are two kinds of solid organic fertilizer products sold in the market: powder and granule. First of all, there is a certain disparity between the two in terms of price, so what are the differences in other aspects? This article discusses the difference between organic fertilizer powder and ...Read more »

-

The organic fertilizer dryer is mainly used to dry granular materials within a certain humidity range, and is suitable for areas with relatively developed large, medium and small aquaculture industries. The increasing maturity of the production and manufacturing technology of organic fertilizer d...Read more »

-

This equipment is used to deodorize the waste gas generated in the process of waste processing by biological bacteria, and discharge the waste gas after it meets the national standard. This equipment is the first choice for livestock manure and fertilizer processing enterprises. Read more »

-

The roulette type turning and throwing machine is driven by a chain in the middle, which drives two large-diameter turning and throwing roulettes for symmetrical turning. Equipped with no dead angle, adjustable speed, displaceable trolley, which is convenient for left and right displacement, and...Read more »

-

A detailed introduction to the types of organic fertilizers Carbonaceous materials are mainly derived from plants and/or animals and are applied to soil to provide plant nutrition as their main function. It is processed from biological materials, animal and plant wastes, and plant residues, which...Read more »

-

Because the aquaculture industry washes manure with water, the waste produced has a relatively high content of water or urine. First, solid-liquid separation is carried out, the liquid is made into liquid fertilizer, and the solid manure is made into powder fertilizer or granular fertilizer. The ...Read more »

-

The sludge fertilizer making equipment extracts qualified sludge through solid fermentation and sterilization, and then uses the nitrogen, phosphorus, potassium and other components contained in the sludge to make organic fertilizer. In this process, biological agents can also be added to make b...Read more »

-

Extrusion granulation is a relatively new dry granulation process for producing compound fertilizers. In the field of fertilizers, extrusion granulation was first used in the granulation of pharmaceuticals, that is, granular (1-4mm) pharmaceuticals required for blending fertilizers (BB fertilizer...Read more »

-

In the production process of rubber products, a large amount of hydrogen sulfide waste gas will be generated. Hydrogen sulfide is a strong neurotoxin and has a strong stimulating effect on the mucous membrane. Hydrogen sulfide is flammable and can form an explosive mixture when mixed with air, wh...Read more »

-

The equipment converts the waste after the production of biogas-biogas slurry and biogas residue into liquid fertilizer and solid fertilizer, solving the problem of difficult discharge and secondary pollution to the environment, truly turning waste into treasure, saving energy and environmental p...Read more »

-

With the continuous growth of the organic fertilizer market, the equipment for manufacturing fertilizers is also being actively improved. So what are the differences between the roller extrusion granulator and the disc granulator? The first type is a pair of roller extrusion granulator, which is ...Read more »

-

The production line adopts double roller fertilizer granulator as granulation equipment. The double roller fertilizer granulator is a new type of granulation equipment, which has been recognized by our customers because of its green and convenient granulation method. The extrusion granulation li...Read more »

-

Extrusion granulation is the most commonly used granulation method in the fertilizer industry, which can produce high, medium and low content fertilizers. The fertilizer granules produced by this granulation are cylindrical and can be rounded to achieve round granules. The selected raw materials...Read more »

-

The fertilizer produced by the chicken manure organic fertilizer equipment contains a lot of quick-acting nutrients. It is not only an ideal base fertilizer, but also can be used as top-dressing fertilizer (top-dressing is a nutrient supplement supply method during crop growth). After the organic...Read more »

-

When the organic fertilizer production line produces high-end fertilizers, the coating machine plays a pivotal role as the last process before packaging. It is responsible for the further polishing and processing of the finished fertilizer, making it a leap forward in appearance and even efficacy...Read more »

-

The intrinsic quality of organic fertilizer mainly depends on the fermentation part and the formulation of the product. The key factors in the fermentation part are: microorganisms, carbon-nitrogen ratio, carbon-phosphorus ratio, moisture, pH value, and ventilation control. If one factor is not w...Read more »

-

1. Intermediate temperature stage In the initial stage of compost production, the microorganisms in the compost are mainly medium temperature and aerobic species, and the most common are non-spore bacteria, spore bacteria and molds. They start the fermentation process of composting, vigorously re...Read more »

-

Different organic fertilizer granulation processes require different types of granulators, which directly affect the production, quality, appearance and price of the product. It can be said that the organic fertilizer granulator is the core of the whole production line. Which granulator is suitab...Read more »

-

Compound fertilizer: refers to the fertilizer made by chemical method and (or) mixing method with at least two of the three nutrients of nitrogen, phosphorus and potassium. (At least two nutrients mentioned here are the basis of compound fertilizers. Otherwise, they are simple fertilizers or elem...Read more »

-

Cattle digest feed more thoroughly and the content of digestible substances such as protein and fat in cow manure is lower, mainly crude fiber. And due to complete digestion, the feces have fine texture, high water content, difficult to ventilate, and low fermentation temperature. Organic cow man...Read more »

-

As the saying goes, “fertile water does not flow to strangers’ fields”. The “fertile water” here refers to human and animal fertilizers. Today, one of the most direct ways to turn chicken manure waste into treasure is to use the organic chicken manure fertilizer equi...Read more »

-

In recent decades, water and fertilizer resources have been consumed and wasted seriously in agricultural production. The shortage of water and fertilizer resources has become more and more prominent with the development of agriculture. Water and fertilizer conservation is an inevitable need for ...Read more »

-

The main actors in the composition of compound fertilizer production costs include raw material costs, variable manufacturing costs, and fixed manufacturing costs. First of all, let’s talk about the control of raw material costs: 1) Try to use cost-effective raw materials. 2) Reduce...Read more »

-

What are the specific functions of bio-organic fertilizer? Next, we will explain them one by one. 1. Provide crop nutrients Organic fertilizers contain a large amount of organic matter, which is slowly decomposed by microorganisms after being applied to the soil, and some of them will become si...Read more »

-

Preparation Tools: mixer; plastic container or cement pool (or soil pit pad plastic film); plastic film; pulverizer (ordinary agricultural type); shovel; turning machine. Fermentation strains: Cow dung starter. Formula 1: 1000 kg of dry cow dung, 0.25 kg of cow dung starter strain, Formula 2: 700...Read more »

-

Organic fertilizer project has a short construction period, high return on investment, low market risk (organic fertilizer generally has a shelf life of at least 5 years), and short payback period (in case of busy farming, supply exceeds demand). The investment can be recovered in the year and pr...Read more »

-

Regulation can be a powerful business stimulus. For the Town of Lexington, Massachusetts, state regulation proved to be a huge municipal benefit as well. When the Massachusetts yard waste recycling mandate took effect in 1987, the visionary leaders in Lexington converted an outdated, unused 30-ac...Read more »