New Delivery for Completely Fertilizer Pellet Production Line - Rotary Drum Fertilizer Granulator – Exceed

New Delivery for Completely Fertilizer Pellet Production Line - Rotary Drum Fertilizer Granulator – Exceed Detail:

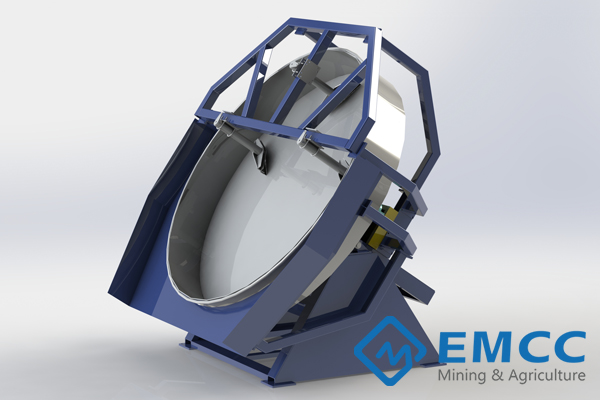

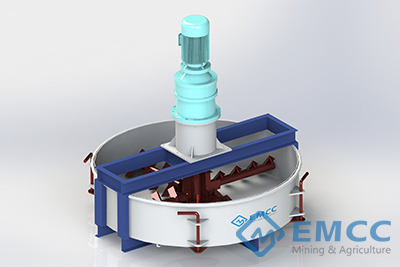

Rotary drum fertilizer granulator is one of the critical machines in compound fertilizer production line. It is applied to cold,hot granulation and quantity production of high,medium or low concentration compound blending fertilizer. The granulating method is rolling round fertilizer particles in wet granulation. With water or vapour added, the original fertilizer in rotary drum are blended uniformly and become humid, during this process, the fertilizer reacts and by way of the liquid environment and rotation in drum, the fertilizer particles squeeze each other and roll into fertilizer particles.The formed fertilizer particles are of 3-4mm.

Advantage

1.High fertilizer particles rolling rate about 70%, less returning fertilizer created,but can be regranulated.

2.Vapour or water adding improves fertilizer temperature and creates high quality fertilizer particles.

3.Engineering plastics are used for inner lining, no stick to liners,Anti-corrosion and thermal insulation.

4.Large granulating capacity,low enrgy consumption and low maintenance cost.

5.Flexible fertilizer particles diameter according to different formulation, processing procedure and raw materials.

6.Super quality steel materials,strict quality requirements and control.

7.Low noise,stable performance;rational structure like shoveling plates to clean drums.

Working principle

The raw materials enter into the rotary drum granulator by the belt conevyor. With the constant rotating of drum, the materials form a rolling bed, and moves along a certain path. Under the extrusion force produced, the materials agglomerate into small particles, which become the core, attaching the powder around to form the qualified spherical granules. The rotary drum is placed obliquely, the granules formed flow out through the outlet of the granulator. The shovelling plates inside the drum help granulating and cleaning

Technical Parameters

| Model | Inner diameter (mm) | Length (mm) | Working speed (r/min) | Capacity (t/h) | Angle (°) | Power (kw) |

| GL-1240 | 1200 | 4000 | 17 | 1-3 | 2-5 | 5.5 |

| GL-1560 | 1500 | 6000 | 11.5 | 3-5 | 2-5 | 11 |

| GL-1870 | 1800 | 7000 | 11.5 | 5-8 | 2-5 | 15 |

| GL-2080 | 2000 | 8000 | 11 | 8-15 | 2-5 | 18.5 |

| GL-3210 | 3200 | 10000 | 9.5 | 15-30 | 2-5 | 37 |

Product detail pictures:

Related Product Guide:

Massive structures emerge as CF construction progresses | A1 | Fertilizer Granulating Machine

Digital Publishing And Content Streaming Top Manufacturers and Uses | Organic Liquid Fertilizer Manufacturers

Our workforce through professional training. Skilled professional knowledge, solid sense of service, to fulfill the services demands of consumers for New Delivery for Completely Fertilizer Pellet Production Line - Rotary Drum Fertilizer Granulator – Exceed, The product will supply to all over the world, such as: Paris , Comoros , Melbourne , Our company will continue to adhere to the " superior quality, reputable, the user first " principle wholeheartedly. We warmly welcome friends from all walks of life to visit and give guidance, work together and create a brilliant future!

Customer service staff and sales man are very patience and they all good at English, product's arrival is also very timely, a good supplier.