Manufacturing Companies for Powder Sifting Machine - Rotary Drum Screen – Exceed

Manufacturing Companies for Powder Sifting Machine - Rotary Drum Screen – Exceed Detail:

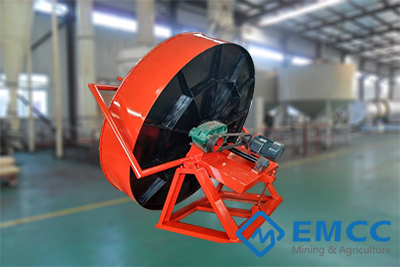

In fertilizer production, the fertilizer granular shall be screened before packaging to ensure the uniformity of the finished product. Rotary drum screen is a common equipment used in the fertilizer industry for compound fertilizer and organic fertilizer production. Rotary durm screen is mainly used in the fertilizer production line to separate finished product and returning materials. The fertilizer sieving machine can also be used for classifying the finished product.

Advantage

1. Adopt combined screen which is easy for maintenance and replacement.

2. High screening efficiency, reducing labor intensity.

3. The driving part adopts pin coupling, making it convenient for assembly and maintenance.

4. Reasonable structure, stable operation, no damage to the rotary machine.

5. Sealed dust cover is installed outside the rotary sieve, eliminating flying dust, improving the working environment.

6. The sealed dust cover also helps isolate the noise produced during operation.

7. Being used in organic & compound fertilizer production lines, behind fertilizer cooling machine.

Range of Application :

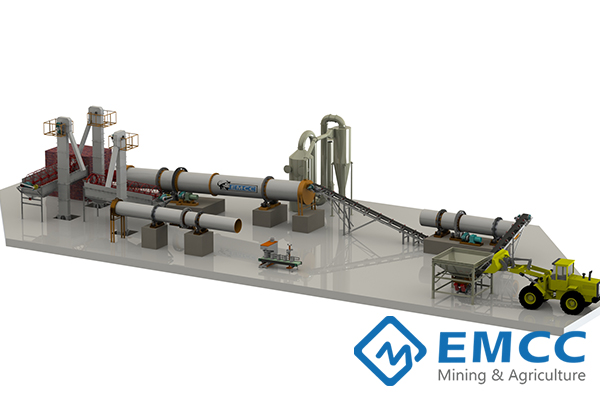

Rotary drum screen is used in many industries such as fertilizer production, steel making, mining, quarrying, foundries, food processing and chemical industry for the separating of bulk materials like compound fertilizers, organic fertilizers, stone aggregates, different kind of sand, active carbon and other materials.

Working principle

Rotary drum screen consists of five parts, including hexagonal drum, rack, funnel, reducers and motor. After the fertilizer granules go into the drum, it is screened by the rotating of the drum, and on the other hand, granules with large size move forward along the drums gradient, screened gradually through different screen.

Technical Parameters

| Model | Working speed (r/min) | Installation Angle (°) | Capacity (t/h) | Reducer model | Power (kw) |

| GTS-1020 | 21 | 2-2.5 | 1-2 | ZQ250 | 3 |

| GTS-1030 | 21 | 2-2.5 | 2-3 | ZQ250 | 3 |

| GTS-1240 | 18 | 2-2.5 | 3-5 | ZQ250 | 4 |

| GTS-1540 | 16 | 2-2.5 | 5-8 | ZQ350 | 5.5 |

| GTS-1560 | 16 | 2-2.5 | 6-10 | ZQ350 | 5.5 |

| GTS-2080 | 12 | 2-2.5 | 10-20 | ZQ450 | 11 |

Product detail pictures:

Related Product Guide:

Liquid fertilizer Market: Global Industry Analysis, Trends, Market Size & Forecasts to 2023 | Organic Fertilizer Products

Halide Minerals Market to Product Innvoation to Stay Ahead in the Game 2025 | Organic Fertilizer Products

We not only will try our greatest to offer you excellent services to each individual client, but also are ready to receive any suggestion offered by our buyers for Manufacturing Companies for Powder Sifting Machine - Rotary Drum Screen – Exceed, The product will supply to all over the world, such as: Porto , Istanbul , Moldova , We've got constructed strong and long co-operation relationship with an enormous quantity of companies within this business in Kenya and overseas. Immediate and professional after-sale service supplied by our consultant group has happy our buyers. Thorough Info and parameters from the merchandise will probably be sent for you for any thorough acknowledge. Free samples may be delivered and company check out to our corporation. n Kenya for negotiation is constantly welcome. Hope to get inquiries type you and construct a long-term co-operation partnership.

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!