High Quality for Gypsum Fertilizer Granulating Machine - Scrubber – Exceed

High Quality for Gypsum Fertilizer Granulating Machine - Scrubber – Exceed Detail:

Gas gets into the scrubber tangentially through the bottom air intake, under the action of the fan, quickly filled the air intake segment space, and then flow evenly through uniform flow section up to the first stage feeding absorption section.

Advantage

Small resistance, low consumption, low noise, high purification efficiency, compact structure, small cover space, good corrosion resistance and aging resistance, light weight.

Gas gets into the scrubber tangentially through the bottom air intake, under the action of the fan, quickly filled the air intake segment space, and then flow evenly through uniform flow section up to the first stage feeding absorption section. On the surface of the filler, the pollutants in gas phase react with the liquid phase substance. The reaction resultant (mostly soluble salts) flowing into the lower portion of the reservoir with the absorption liquid. The gas not completely absorbed continues rises into the spray section. The absorption liquid sprays in high-speed through the uniformly distributed nozzle in the ejection segments, generating numerous small droplets continue react with the gas. This treatment can cool the exhaust gas to remove particles and other impurities. The tower uppermost segment is for defogging, and the absorbing liquid droplets carried by gas are cleared here. The treated clean air is blown into the atmosphere through the upper end of the scrubber.

Scrubber Model and Parameters

The Scrubber has A, B and C three models. A model is wet scrubber. B model is acid and alkaline gases scrubber. C model is organic gases and heat gases scrubber.

A Series Scrubber Parameters

| Organic Wet Scrubber | |||||

| Model | Air volume m³/h | Diameter (mm) | Height (mm) | Inlet Opening (mm) | Outlet Opening (mm) |

| GVT- 04 | 3000 | Φ1500 | 4500 | 300 | 300 |

| GVT- 05 | 5000 | Φ1800 | 5000 | 400 | 400 |

| GVT- 06 | 10000 | Φ2600 | 5500 | 550 | 550 |

| GVT- 07 | 15000 | Φ3200 | 6000 | 700 | 700 |

| GVT- 08 | 20000 | Φ3600 | 6200 | 800 | 800 |

| GVT- 09 | 25000 | Φ4200 | 6500 | 900 | 900 |

| GVT- 10 | 30000 | Φ4600 | 7500 | 1000 | 1000 |

| Note: Two layers of spray, two layers of fillings, empty tower speed 0.5m / s. | |||||

B Series Scrubber Parameters

| Acid and Alkaline Gases Scrubber | |||||

| Model | Air Volume m³/h | Diameter (mm) | Height (mm) | Inlet Opening (mm) | Outlet Opening (mm) |

| XST- 04 | 3000 | Φ1030 | 4300 | 300 | 300 |

| XST- 05 | 5000 | Φ1300 | 4600 | 400 | 400 |

| XST- 06 | 10000 | Φ1800 | 4750 | 550 | 550 |

| XST- 07 | 15000 | Φ2300 | 4840 | 700 | 700 |

| XST- 08 | 20000 | Φ2600 | 5500 | 800 | 800 |

| XST- 09 | 25000 | Φ3000 | 6200 | 900 | 900 |

| XST- 10 | 30000 | Φ3200 | 6500 | 1000 | 1000 |

| XST- 11 | 35000 | Φ3500 | 6700 | 1100 | 1100 |

| Note: Two layers of spray, two layers of fillings, empty tower speed 0.5m / s. | |||||

C Series Scrubber Parameters

| Organic Gases and Heat Gases Scrubber | |||||

| Model | Air Volume m³/h | Diameter (mm) | Height (mm) | Inlet Opening (mm) | Outlet Opening (mm) |

| XDT- 04 | 3000 | Φ750 | 3965 | 300 | 300 |

| XDT- 05 | 5000 | Φ900 | 4015 | 400 | 400 |

| XDT- 06 | 10000 | Φ1330 | 4430 | 550 | 550 |

| XDT- 07 | 15000 | Φ1620 | 4630 | 700 | 700 |

| XDT- 08 | 20000 | Φ1880 | 4840 | 800 | 800 |

| XDT- 09 | 25000 | Φ2100 | 5000 | 900 | 900 |

| XDT- 10 | 30000 | Φ2300 | 5300 | 1000 | 1000 |

| XDT- 11 | 35000 | Φ2500 | 5500 | 1100 | 1100 |

| XDT- 12 | 40000 | Φ2660 | 6000 | 1180 | 1180 |

| XDT- 13 | 45000 | Φ2800 | 6100 | 1200 | 1200 |

| XDT- 14 | 50000 | Φ3000 | 6200 | 1330 | 1330 |

| Note: Two layers of spraying, two layers of filled, empty tower speed 2 m / s. | |||||

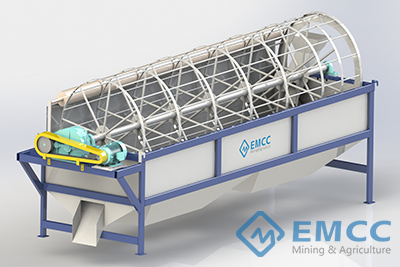

Product detail pictures:

Related Product Guide:

Halide Minerals Market to Product Innvoation to Stay Ahead in the Game 2025 | Organic Fertilizer Products

Viewpoint: Moving to cleaner and more efficient power on the MSU campus | Organic Liquid Fertilizer Manufacturers

As for competitive charges, we believe that you will be searching far and wide for anything that can beat us. We will state with absolute certainty that for such excellent at such charges we have been the lowest around for High Quality for Gypsum Fertilizer Granulating Machine - Scrubber – Exceed, The product will supply to all over the world, such as: Moscow , Hanover , Madras , Meanwhile, we're building up and consummating triangle market & strategic cooperation in order to achieve a multi-win trade supply chain to expand our market vertically and horizontally for a brighter prospects. development. Our philosophy is to create cost-effective products, promote perfect services, cooperate for long-term and mutual benefits, firm a comprehensive mode of excellent suppliers system and marketing agents, brand strategic cooperation sales system.

This is a very professional and honest Chinese supplier, from now on we fell in love with the Chinese manufacturing.