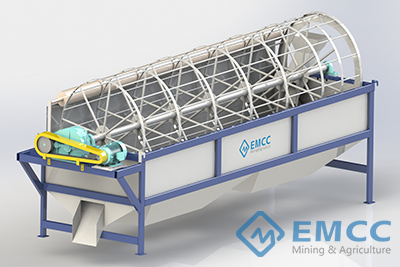

Excellent quality Gypsum Fertilizer Granules Making Machine - Disc Mixer – Exceed

Excellent quality Gypsum Fertilizer Granules Making Machine - Disc Mixer – Exceed Detail:

The disc mixer is mainly applied to the compound fertilizer plant. By using the optimum quality material and leading technology, this fertilizer mixing machine complies with industry standards and international specifications. It is popular with our customers due to its high efficiency, competitive price, easy operation and low maintenance cost. In the compound fertilizers production line, it is placed before the fertilizer granulator to uniformly mix the raw materials before the granulation.

Advantage

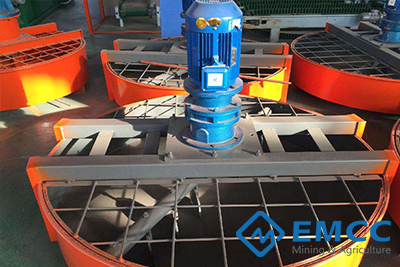

1. Robust structure. It is made of steel, resistant to abrasion, wear resistance, durable.

2. Design and rational configuration. PVC padded plate to avoid sticking the inner lining.

3. Cycloidal reducer, high speed and efficiency, energy saving.

4. Mixing and crushing material, easy to operate and unload materials.

5. Can work independently or match with the fertilizer plant.

Principle of Work

The entire mixing process is driven by the main shaft after starting the engine. There are several stirring blades welded on the main shaft and small shovels are placed on each stirring blade. Feed the fertilizers in the cylinder. It is the shovels and the agitation blades that play an important role in the homogeneous mixture of materials. Then open the discharge door to place the average mixed fertilizer. As the material is not very wet, it almost does not stick to the shovels or stirring blades, so it is not necessary to clean the machine.

Technical Parameter

| Model | Dimension

(mm) |

Disc Depth

(mm) |

Disc Diameter (mm) | Power

(kw) |

Mixing Speed

(r/min) |

Capacity

(t/h) |

| PJ-1600 | 1600x1600x1800 | 400 | 1600 | 7.5 | 16 | 2-4 |

| PJ-1800 | 1800x1800x1800 | 400 | 1800 | 7.5 | 16 | 3-5 |

| PJ-2000 | 2000x2000x1800 | 400 | 2000 | 7.5 | 16 | 4-6 |

| PJ-2200 | 2200x2200x1850 | 400 | 2200 | 7.5 | 16 | 6-8 |

| PJ-3000 | 3000x3000x2000 | 400 | 3000 | 15 | 16 | 8-12 |

Product detail pictures:

Related Product Guide:

Dangote Refinery Will Save Nigeria $26bn Yearly-Expatriate | Organic Fertilizer Plant

Global Potassium Thiosulfate Fertilizer Market Analysis Report 2018-2025:Spraygro Liquid Fertilizer, Plant Food Company, Kodia Company | Fertilizer Granulating Machine

The key to our success is "Good Product or service High quality, Reasonable Rate and Efficient Service" for Excellent quality Gypsum Fertilizer Granules Making Machine - Disc Mixer – Exceed, The product will supply to all over the world, such as: New Zealand , moldova , Norway , Our faith is to be honest first, so we just supply high quality products to our customers. Really hope that we can be business partners. We believe that we can establish long time business relationship with each other. You can contact us freely for more information and pricelist of our products !

Managers are visionary, they have the idea of "mutual benefits, continuous improvement and innovation", we have a pleasant conversation and Cooperation.